Greenbelt Certification Sample

A sample to reference

Project Introduction:

Date: June 27th, 20XX

Company Name: Minnesota Manufacturing, Inc.

Applicant: Kirby Sneen, Sr. Manufacturing Engineer

The Project Name: 6 Sigma Improvement Project for Warranty Returned Goods

The Team:

Bill Kearney – Quality Manager & Project Leader

Dick Fettig – Information Services

Joey Lloyd – Supplier Quality Engineer

Maxine Maples – Department Lead

Tony Moline – Quality Technician

Susan Schinke – Customer Service

The Company Description:

Minnesota Manufacturing (2M) is located in Plymouth, Minnesota. They manufacture pumps, motors and accessories. They sell nation-wide to the industrial pump market, and they are a privately held firm.

Approvals:

Manager: Brian Martin 6-26-20XX

Name: Brian Martin, VP Operations

Peer: Larry Fong 6-26-20XX

Name: Larry Fong, Mfg. Engineer

Problem Statement:

Warranty returns are a major contributor to our Cost of Quality (COQ). It is one of the company’s strategic initiatives to reduce the COQ this year. Our highest sales volume motor is incurring $60,000 in annualized warranty costs out of $120,000 total in claims. This fix needs prompt attention to improve the customer experience and resolve complaints.

Timeline:

| Action | Due | Owner |

| Project selection and approval, team selection | 2-1 | Kirby Sneen |

| Write the project charter, scope and plan | 2-18 | Kirby Sneen |

| Meet with IS to get historical baseline data | 3-28 | Kirby Sneen |

| Pareto failure modes and contact supplier for causes | 4-22 | Maxine Maples |

| Engineering redesign based on supplier input | 5-27 | Kirby Sneen |

| Implement new supplier quality inspection and monitor on-going warranty claims. | 6-3 | Kirby Sneen |

| Review project warranty data and determine project results | 6-27 | Kirby Sneen |

Current State:

This product is 50% of our total warranty expense of $120,000, equating to $60,000 in annualized warranty expense.

Goals:

| Goal | Current |

| Goal 1: Reduce warranty expense by 50% | $60,000/yr. warranty expense

|

Major Project Activities and Challenges:

DEFINE:

- Defined the Project

- Created the Project Definition

- Project Objective

- Project Scope

- Key Challenges and Goals

- Identified Customers as External (Vendor) and Internal (Receiving, Customer Service, Production, and Accounts Receivable)

- Completed the milestone chart showing milestones, responsible person and dates

- Collected costs for the current process to be used for potential cost savings

- Completed a flowchart of the process

MEASURE:

- The team discussed the best measurements to use.

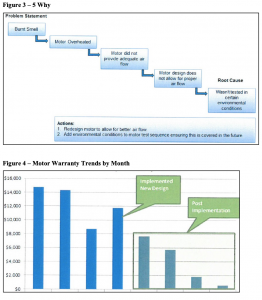

- IT provided a data base of the required warranty data (see Warranty Trend chart)

- Maxine H. gathered data for the Warranty Failure Modes (see Failure Mode chart)

- Data was reviewed by team

ANALYZE: The team –

- Brainstormed ideas by category (see Fishbone chart)

- Identified root causes by asking 5 Whys (see 5 Why diagram)

- Kirby documented results

IMPROVE:

- Bill received approval from upper management for the redesign

- Bill trained and communicated changes internally and externally

CONTROL:

- Kirby wrote internal procedures for motor test sequence

- Tony wrote new test frequency for heightened inspection for next 6 months

- Bill wrote on-going audit process to maintain fix.

Tools from Workshops used

Pareto chart

Fishbone Diagram

5 Whys

Trend Chart

Results & Final Conditions:

| Goal | Current | After | Results |

| Goal 1: Reduce warranty expense by 50% | $60,000/yr. warranty expense | Warranty expense reduced by $45,000.

New expense: $15,000 |

Reduced from $60,000 to $15,000.

Improved by 75% |

Sustainment

I have added a daily audit of the process to my leader standard work. This will scale back to weekly then monthly over time. The team will be alerted should the internal team find an issue related to the improvements related to this motor.

Conclusions/Lessons Learned

We saw great results with this project, and this is especially important because it was among the first Six Sigma projects for Minnesota Mfg. The leadership team has a high interest in doing additional projects because there are a lot of other motors in the family to fix as well. The support of Minnesota Mfg. personnel for this project was very good since it had top management support. It took longer than the engineers were comfortable with, but everyone eventually bought into the changes.

One of the unintended benefits is that we have had a positive response from our customers. Improving customer satisfaction has a strong link to supporting the strategic goals of the company.